Показаны сообщения с ярлыком quality. Показать все сообщения

Показаны сообщения с ярлыком quality. Показать все сообщения

воскресенье, 10 декабря 2023 г.

воскресенье, 30 апреля 2017 г.

The 10 Biggest Quality Mistakes

One of the most effective ways to improve is to learn from other people’s mistakes. Experience has taught me that there are plenty of mistakes out there to learn from. The trick is to recognize them and understand what to do instead. Unfortunately, I keep seeing the same mistakes over and over. They aren’t mistakes because they violate a standard such as ISO 9001; they’re mistakes because they violate good sense. Let’s examine the 10 most common quality mistakes and see how they can be corrected.

1. Limiting quality objectives to traditional quality topics

The term “quality objective” is an unfortunate one. It introduces subjectivity (i.e., quality) into a subject that should be quite clear (objectives). A much better term would simply be “measurable objectives” because that requires less interpretation. The word “quality” clouds the issue and makes many people want to narrow the focus of what a quality objective can be.

The truth is that quality is reflected in everything an organization does, and a quality objective can be anything measurable that relates to the organization’s success. A quality objective might relate to finances, customer feedback, safety, efficiency, speed or innovation. All these attributes relate to quality in one way or another. When selecting quality objectives, organizations should examine what matters most to their success. Whether the resulting measure is tied to traditional quality control or quality assurance is irrelevant.

2. Holding infrequent management reviews

Management review is the process used by top management to analyze data, make decisions and take action. Ideally, it’s a preventive process because data should indicate threats before they blossom into full-blown problems. If top managers are unable to analyze data proactively and prevent problems, then they’re not doing their jobs. Holding management reviews once or twice a year ensures that actions taken won’t be preventive. Only through timely and frequent data review can actions be preventive. Once or twice a year won’t cut it.

Many people argue that their organizations already review data on a weekly and monthly basis. This means that management review is still after the fact; the decisions have already been made. Management review must be included in existing meetings. Instead of a twice-yearly dog-and-pony show, cover the inputs and outputs of management review as they occur naturally during existing meetings. After a month or two, you’ll have addressed all the required inputs and outputs. Using this approach, you’ll have information that’s timely and resulting actions that are preventive. Another advantage is that you dispense with the need for long, laborious management reviews. They happen in a smooth and effective manner that’s much more likely to drive improvements.

3. Sending out long, complex customer surveys

The days of the long and complicated customer survey are over. People don’t have time to complete them. Even when organizations design shorter surveys, the questions are often confusing and fraught with interpretation problems. The scales that accompany the questions are often unbalanced and illogical. As a result, organizations end up with a small amount of valid data. Better to have no data at all than data that could lead you in the wrong direction.

Instead of a survey, why not simply ask your customers what they like and dislike? Don’t limit their responses to survey topics. Let your customers dictate the content of their feedback in response to open-ended questions. Few are more powerful than the following: What do you like? What don’t you like? What would you like to see different in the future? Open-ended feedback is also much easier to understand and take action on. A customer- satisfaction index of 3.8 is hard to interpret. On the other hand, seven out of 10 customers telling you that your Web site is confusing is very easy to interpret.

4. Assuming everyone knows what “nonconforming” looks like

When I visit organizations, one of my favorite questions is, “Where do you put the nonconforming products?” Control of nonconforming products is one of the most basic kinds of controls, and it speaks volumes about the rest of the controls embraced by the organization. Unfortunately, where I often find nonconforming products is wherever someone decided to leave them. They’re not uniquely identified, either. In other words, nonconforming products are treated no differently than any other products. When I ask why this is happening, the most common answer I get is, “Because everyone knows that’s nonconforming.” No, they don’t. No matter how nonconforming a product is, there will be someone who won’t recognize it as such. The stories of bent, broken and blown-up products that somehow got used anyway aren’t urban legends. They’re true.

Smart organizations positively identify all nonconforming products, and really smart organizations segregate them to remove all chance of accidental use. Error-proof your control of the nonconforming product process so that nobody has to assume anything.

5. Failing to use the corrective action process

Corrective action is the systematic way to investigate problems, identify their causes and keep the problems from happening again. Nobody wants problems, but it’s essential to have a way of dealing with them when they come up. The more the corrective action process is used, the better the organization gets at addressing its risks and problems. That’s why I’m astounded when I hear about organizations that avoid using their corrective action processes. Of course, I always ask why they’re doing this, and I often get one of these answers:

• Corrective action isn’t effective for large problems.

• Corrective action isn’t effective for small problems.

• Nobody understands root cause.

• Our problem-solving tools are confusing.

• Our procedure requires too much paperwork.

• Corrective action takes too long.

• I hate our corrective action form.

• Top management frowns on corrective action because it means that someone screwed up.

These aren’t corrective action problems but problems with the organization’s approach to corrective action. An effective corrective action process is typically seamless, simple and intuitive. The whole point is to add a little structure to problem solving, not to create additional bureaucracy.

Here are some hints to make your corrective action process more user friendly and effective:

• Strip it down to the essentials. A corrective action must clearly describe the problem, how it’s caused, actions taken to remove the causes, results of actions taken and how the actions were effective. Only include additional elements when you can prove that they add value.

• Remove all jargon from the process. Strange words only discourage people from using the process.

• Don’t insist on a raft of signatures . It’s not necessary for half the management staff to sign off on every corrective action.

• Remove paper from the process as much as possible. Use electronic media to track corrective actions.

• Communicate corrective actions widely. When people see that corrective actions accomplish something, they’re much more likely to participate in the process.

• Provide problem-solving tools, but give people some discretion in their use . If your procedure requires a failure mode and effects analysis to be completed for every corrective action, it will probably discourage people from starting corrective actions.

• Use teams for corrective actions whenever possible. This gives people experience in the process and also increases the effectiveness of most solutions.

6. Applying document control only to official documents

Most organizations do a decent job of controlling “official” documents, the procedures and work instructions that form the core of the quality management system (QMS). These are often written, approved and issued according to very specific guidelines. What organizations don’t do very well is control unofficial documents, many of which are more important than the official ones. What am I talking about? Here are some examples that are often found in production areas:

• Post-it notes with special requirements written on them

• Memos that include procedural steps

• E-mails with customer specifications

• Photographs showing what a product should look like

• Drawings indicating how product components fit together

• Samples of product showing defect limits

These informal resources become documents when they’re shared for people to

use, and they’re some of the most important documents within an organization. They’re distributed and posted in a hurry--usually without control--because the information they communicate is considered critical. Nobody can quibble with the speed of distribution, but the lack of control guarantees problems later. I’ve seen 10-year-old memos posted in organizations that exhorted personnel to perform obsolete job steps. When documents aren’t controlled, mistakes and nonconformities are inevitable. Apply document control to all documents, and scrutinize your document control process to keep it streamlined and effective.

7. Focusing audits on petty, nonstrategic details

Auditing is the process of comparing actual operations against commitments the organization has made. It’s a simple, fact-driven process that can generate huge improvements. However, these can occur only if auditors focus on the right things. Too often, internal auditors become preoccupied with petty details and neglect the big issues. They’re uncomfortable examining the big, strategic issues. It’s much easier just to nitpick. Organizations rarely provide enough training and skill-building to their internal auditors, so it’s no wonder that they aren’t prepared to carry out their duties to the fullest.

A robust internal auditing process examines make-or-break issues. Here are just a few of the items that internal auditors should probe in detail:

• Customer satisfaction. Is the organization capturing and analyzing customer satisfaction data? How is it acting on the data? Do trends show improvements in customer satisfaction?

• Management review. Does management review happen as planned? Does the necessary information and data get reviewed? What actions result?

• Corrective action. Is corrective action applied to existing nonconformities? Is it timely? Does evidence indicate that causes are removed to prevent recurrence?

• Preventive action. Does the organization take preventive action based on data and information? Is it effective?

• Internal audits. Are audits scheduled and carried out based on status, importance and prior audit results? Do audit nonconformities become corrective actions? Is the entire scope of the management system audited?

• Objectives. Are objectives established and communicated? Do employees understand them?

• Control of nonconforming products. Are all nonconformities positively identified? Are dispositions carried out as required? Are trends analyzed for improvement?

There are, of course, many other important issues an audit process could examine. The point is that internal auditors should go after the items that really affect the organization’s success. Focusing on petty details serves no purpose but to confuse everyone about the purpose of audits.

8. Training some personnel, but not all

Most organizations provide significant training to hourly production personnel. Salaried and managerial personnel are often neglected, however. Why? Because there’s a perception that salaried workers don’t affect product conformity. This is a serious error.

All personnel must be included in the training process. Salaried and managerial personnel need more--not less--training because their decisions and actions have more lasting effects. When an hourly employee makes a mistake, it could cost money. When a top manager makes a mistake, it could put you out of business. Doesn’t it make sense to train these people? Do it early and often.

9. Doing anything just because an external auditor told you to

External auditors wield great influence. Their statements and judgments can have a lasting effect on the way an organization conducts business. This can be good or bad. Usually, it’s bad. Most external auditors working for a registrar are removed from the realities of running a business. They travel from organization to organization, gradually collecting paradigms about the way a QMS should be implemented, maintained and improved. These paradigms are sometimes reflected back to the organization in the form of recommendations or nonconformities.

In my travels to companies, I often ask people why they’re carrying out a process the way they are. I always raise this question when the process seems unwieldy or illogical. In a surprising number of cases, the answer will be, “Because the external auditor said we should do it that way.” What a waste. Do a reality check on the auditor’s recommendations. Never do anything just because an auditor would like it done that way. A certificate on the wall isn’t worth it.

10. Employing someone who only oversees the QMS

Having a person who does nothing but oversee the ISO 9001 (or any other) QMS is one of the worst ideas in the history of quality. Why? Because it guarantees two things:

First, the QMS coordinator will become isolated from the rest of the organization. Because the person does nothing but serve the QMS, he or she loses touch with why the organization exists in the first place. The system becomes paramount over the organization’s business concerns. Second, the QMS will become bloated and bureaucratic because it must expand to completely fill someone’s time. Procedures become more complicated, methods more cumbersome and the benefits more ambiguous.

A QMS is nothing more than a guiding structure of methods, and it shouldn’t take a huge dedication of time and effort to maintain. Yes, someone should keep the system on track, but that person should have other responsibilities as well. Pair the ISO 9001 coordinator job with other responsibilities that focus on understanding what the organization does, especially responsibilities related to the product, customers and improvement. If the QMS is so bureaucratic that it requires the time of an entire person (or, heaven forbid, an entire staff), then the system needs to be streamlined. An effective QMS should make an organization more competitive, not weigh it down.

1. Limiting quality objectives to traditional quality topics

The term “quality objective” is an unfortunate one. It introduces subjectivity (i.e., quality) into a subject that should be quite clear (objectives). A much better term would simply be “measurable objectives” because that requires less interpretation. The word “quality” clouds the issue and makes many people want to narrow the focus of what a quality objective can be.

The truth is that quality is reflected in everything an organization does, and a quality objective can be anything measurable that relates to the organization’s success. A quality objective might relate to finances, customer feedback, safety, efficiency, speed or innovation. All these attributes relate to quality in one way or another. When selecting quality objectives, organizations should examine what matters most to their success. Whether the resulting measure is tied to traditional quality control or quality assurance is irrelevant.

2. Holding infrequent management reviews

Management review is the process used by top management to analyze data, make decisions and take action. Ideally, it’s a preventive process because data should indicate threats before they blossom into full-blown problems. If top managers are unable to analyze data proactively and prevent problems, then they’re not doing their jobs. Holding management reviews once or twice a year ensures that actions taken won’t be preventive. Only through timely and frequent data review can actions be preventive. Once or twice a year won’t cut it.

Many people argue that their organizations already review data on a weekly and monthly basis. This means that management review is still after the fact; the decisions have already been made. Management review must be included in existing meetings. Instead of a twice-yearly dog-and-pony show, cover the inputs and outputs of management review as they occur naturally during existing meetings. After a month or two, you’ll have addressed all the required inputs and outputs. Using this approach, you’ll have information that’s timely and resulting actions that are preventive. Another advantage is that you dispense with the need for long, laborious management reviews. They happen in a smooth and effective manner that’s much more likely to drive improvements.

3. Sending out long, complex customer surveys

The days of the long and complicated customer survey are over. People don’t have time to complete them. Even when organizations design shorter surveys, the questions are often confusing and fraught with interpretation problems. The scales that accompany the questions are often unbalanced and illogical. As a result, organizations end up with a small amount of valid data. Better to have no data at all than data that could lead you in the wrong direction.

Instead of a survey, why not simply ask your customers what they like and dislike? Don’t limit their responses to survey topics. Let your customers dictate the content of their feedback in response to open-ended questions. Few are more powerful than the following: What do you like? What don’t you like? What would you like to see different in the future? Open-ended feedback is also much easier to understand and take action on. A customer- satisfaction index of 3.8 is hard to interpret. On the other hand, seven out of 10 customers telling you that your Web site is confusing is very easy to interpret.

4. Assuming everyone knows what “nonconforming” looks like

When I visit organizations, one of my favorite questions is, “Where do you put the nonconforming products?” Control of nonconforming products is one of the most basic kinds of controls, and it speaks volumes about the rest of the controls embraced by the organization. Unfortunately, where I often find nonconforming products is wherever someone decided to leave them. They’re not uniquely identified, either. In other words, nonconforming products are treated no differently than any other products. When I ask why this is happening, the most common answer I get is, “Because everyone knows that’s nonconforming.” No, they don’t. No matter how nonconforming a product is, there will be someone who won’t recognize it as such. The stories of bent, broken and blown-up products that somehow got used anyway aren’t urban legends. They’re true.

Smart organizations positively identify all nonconforming products, and really smart organizations segregate them to remove all chance of accidental use. Error-proof your control of the nonconforming product process so that nobody has to assume anything.

5. Failing to use the corrective action process

Corrective action is the systematic way to investigate problems, identify their causes and keep the problems from happening again. Nobody wants problems, but it’s essential to have a way of dealing with them when they come up. The more the corrective action process is used, the better the organization gets at addressing its risks and problems. That’s why I’m astounded when I hear about organizations that avoid using their corrective action processes. Of course, I always ask why they’re doing this, and I often get one of these answers:

• Corrective action isn’t effective for large problems.

• Corrective action isn’t effective for small problems.

• Nobody understands root cause.

• Our problem-solving tools are confusing.

• Our procedure requires too much paperwork.

• Corrective action takes too long.

• I hate our corrective action form.

• Top management frowns on corrective action because it means that someone screwed up.

These aren’t corrective action problems but problems with the organization’s approach to corrective action. An effective corrective action process is typically seamless, simple and intuitive. The whole point is to add a little structure to problem solving, not to create additional bureaucracy.

Here are some hints to make your corrective action process more user friendly and effective:

• Strip it down to the essentials. A corrective action must clearly describe the problem, how it’s caused, actions taken to remove the causes, results of actions taken and how the actions were effective. Only include additional elements when you can prove that they add value.

• Remove all jargon from the process. Strange words only discourage people from using the process.

• Don’t insist on a raft of signatures . It’s not necessary for half the management staff to sign off on every corrective action.

• Remove paper from the process as much as possible. Use electronic media to track corrective actions.

• Communicate corrective actions widely. When people see that corrective actions accomplish something, they’re much more likely to participate in the process.

• Provide problem-solving tools, but give people some discretion in their use . If your procedure requires a failure mode and effects analysis to be completed for every corrective action, it will probably discourage people from starting corrective actions.

• Use teams for corrective actions whenever possible. This gives people experience in the process and also increases the effectiveness of most solutions.

6. Applying document control only to official documents

Most organizations do a decent job of controlling “official” documents, the procedures and work instructions that form the core of the quality management system (QMS). These are often written, approved and issued according to very specific guidelines. What organizations don’t do very well is control unofficial documents, many of which are more important than the official ones. What am I talking about? Here are some examples that are often found in production areas:

• Post-it notes with special requirements written on them

• Memos that include procedural steps

• E-mails with customer specifications

• Photographs showing what a product should look like

• Drawings indicating how product components fit together

• Samples of product showing defect limits

These informal resources become documents when they’re shared for people to

use, and they’re some of the most important documents within an organization. They’re distributed and posted in a hurry--usually without control--because the information they communicate is considered critical. Nobody can quibble with the speed of distribution, but the lack of control guarantees problems later. I’ve seen 10-year-old memos posted in organizations that exhorted personnel to perform obsolete job steps. When documents aren’t controlled, mistakes and nonconformities are inevitable. Apply document control to all documents, and scrutinize your document control process to keep it streamlined and effective.

7. Focusing audits on petty, nonstrategic details

Auditing is the process of comparing actual operations against commitments the organization has made. It’s a simple, fact-driven process that can generate huge improvements. However, these can occur only if auditors focus on the right things. Too often, internal auditors become preoccupied with petty details and neglect the big issues. They’re uncomfortable examining the big, strategic issues. It’s much easier just to nitpick. Organizations rarely provide enough training and skill-building to their internal auditors, so it’s no wonder that they aren’t prepared to carry out their duties to the fullest.

A robust internal auditing process examines make-or-break issues. Here are just a few of the items that internal auditors should probe in detail:

• Customer satisfaction. Is the organization capturing and analyzing customer satisfaction data? How is it acting on the data? Do trends show improvements in customer satisfaction?

• Management review. Does management review happen as planned? Does the necessary information and data get reviewed? What actions result?

• Corrective action. Is corrective action applied to existing nonconformities? Is it timely? Does evidence indicate that causes are removed to prevent recurrence?

• Preventive action. Does the organization take preventive action based on data and information? Is it effective?

• Internal audits. Are audits scheduled and carried out based on status, importance and prior audit results? Do audit nonconformities become corrective actions? Is the entire scope of the management system audited?

• Objectives. Are objectives established and communicated? Do employees understand them?

• Control of nonconforming products. Are all nonconformities positively identified? Are dispositions carried out as required? Are trends analyzed for improvement?

There are, of course, many other important issues an audit process could examine. The point is that internal auditors should go after the items that really affect the organization’s success. Focusing on petty details serves no purpose but to confuse everyone about the purpose of audits.

8. Training some personnel, but not all

Most organizations provide significant training to hourly production personnel. Salaried and managerial personnel are often neglected, however. Why? Because there’s a perception that salaried workers don’t affect product conformity. This is a serious error.

All personnel must be included in the training process. Salaried and managerial personnel need more--not less--training because their decisions and actions have more lasting effects. When an hourly employee makes a mistake, it could cost money. When a top manager makes a mistake, it could put you out of business. Doesn’t it make sense to train these people? Do it early and often.

9. Doing anything just because an external auditor told you to

External auditors wield great influence. Their statements and judgments can have a lasting effect on the way an organization conducts business. This can be good or bad. Usually, it’s bad. Most external auditors working for a registrar are removed from the realities of running a business. They travel from organization to organization, gradually collecting paradigms about the way a QMS should be implemented, maintained and improved. These paradigms are sometimes reflected back to the organization in the form of recommendations or nonconformities.

In my travels to companies, I often ask people why they’re carrying out a process the way they are. I always raise this question when the process seems unwieldy or illogical. In a surprising number of cases, the answer will be, “Because the external auditor said we should do it that way.” What a waste. Do a reality check on the auditor’s recommendations. Never do anything just because an auditor would like it done that way. A certificate on the wall isn’t worth it.

10. Employing someone who only oversees the QMS

Having a person who does nothing but oversee the ISO 9001 (or any other) QMS is one of the worst ideas in the history of quality. Why? Because it guarantees two things:

First, the QMS coordinator will become isolated from the rest of the organization. Because the person does nothing but serve the QMS, he or she loses touch with why the organization exists in the first place. The system becomes paramount over the organization’s business concerns. Second, the QMS will become bloated and bureaucratic because it must expand to completely fill someone’s time. Procedures become more complicated, methods more cumbersome and the benefits more ambiguous.

A QMS is nothing more than a guiding structure of methods, and it shouldn’t take a huge dedication of time and effort to maintain. Yes, someone should keep the system on track, but that person should have other responsibilities as well. Pair the ISO 9001 coordinator job with other responsibilities that focus on understanding what the organization does, especially responsibilities related to the product, customers and improvement. If the QMS is so bureaucratic that it requires the time of an entire person (or, heaven forbid, an entire staff), then the system needs to be streamlined. An effective QMS should make an organization more competitive, not weigh it down.

POSTED BY CRAIG COCHRAN

воскресенье, 23 апреля 2017 г.

Factors affecting production

What is meant by production?

Production is the provision of a product to satisfy wants and needs. The process involves businessesadding value to their products. E.g. The production process of matches involve cutting wood into matchsticks, putting phosaphorus ends on them and packaging them to sell.

Productivity

Productivity is the outputs measured against the inputs used to create it. This is measured by:

Production is the provision of a product to satisfy wants and needs. The process involves businessesadding value to their products. E.g. The production process of matches involve cutting wood into matchsticks, putting phosaphorus ends on them and packaging them to sell.

Productivity

Productivity is the outputs measured against the inputs used to create it. This is measured by:

Output (over a given period of time)/Number of employees

If a worker makes more products in the same amount of time, his productivity increases. Firms aim to be productively efficient to be able to make more profits and compete against their competitors.

Methods of production

Job production

Methods of production

Job production

- Goods are made individually, by one person.

- Goods are usually specialized, no two goods are the same.

- Usually made to order.

Pros

- The product meets exact requirements of the customer.

- The workers have more varied jobs.

- More job satisfaction for workers.

Cons

- Skilled labour is needed.

- Slower and more expensive than other methods of production.

- Usually labour intensive.

Batch production

- Products are made in batches according to order.

Pros

- It is flexible. You can easily change from making one product to another.

- Still gives some variety to workers jobs.

- Production is not too affected by machinery breakdown.

Cons

- Expensive to move products around the workplace.

- Storage space will be needed to store raw materials. Expensive.

Flow production

- Large quantities of a product are produced in a continuous process.

- Uses specialization.

- Benefits from economies of scale.

- Is capital intensive.

Pros

- Low costs. Low prices. High sales.

- Increased efficiency.

- Little training is needed.

- Goods are produced quickly and cheaply.

- Goods do not need to be moved around like batch production. Saves time.

- Quality is high and standardized (courtesy to Muhammad Hassaan Ayyub)

Cons

- Boring for the workers. Little job satisfaction.

- Needs a lot of capital to set up.

- If one machine breaks down then the whole production process stops.

Which type of production should be used?

The type of production that should be used varies with how the product is demanded:

The type of production that should be used varies with how the product is demanded:

- Job production: Unique and individual service is required.

- Batch production: Demand is higher but products will not be sold in large quantities. Batches are made to orders.

- Flow production: Demand for the product is high and steady.

Stock control

Stock control is important so that a business will not

run

out of stock and be unable to satisfy demands. When stock levels get to a certain point, more goods need to be reordered for the stock level to reach its maximum again. If more goods are not reordered, stocks could run out because of an unexpected

surge in demand. However, keeping a lot of stock costs money, so the level of stock in a company should always be balanced. The following graph demonstrates how stock can be controlled:

Lean production

- Focuses on cutting down waste, increasing efficiency.

- It tries to reduce the time taken to produce a product and transport it the selling point.

- Includes the following methods:

- Kaizen.

- JIT production.

- Cell production.

- Kanban.

Kaizen

- Continuous improvement through the elimination of waste.

- Ideas of workers.

- Regular meetings of workers to discuss how to increase efficiency.

- Ideas of workers.

- The advantages of Kaizen:

- Increased productivity.

- Reduced amount of space needed for the production process.

- Work-in-progress is reduced.

- Improved layout of the factory floor may combine jobs of some employees, freeing others to do other things.

- Increased productivity.

Just in time production

- Eliminating the need to hold stocks.

- Goods are delivered to the selling point just when they are needed.

- JIT production needs:

- Reliable suppliers.

- Efficient system of ordering raw materials.

Cell production

- Production line is divided into cells.

- Each cell makes an identifiable part of the finished product.

- Boosts morale.

Kanban

- A system of ordering used with JIT production.

- Operates with two component bins.

- When one is emptied, production begins to fill it.

- The other one is then left to be emptied.

- The first one is filled up when the second one is emptied.

Improvements in technology

Here are some things that technology does in the production process:

- Automation: Equipment in the production process is controlled by a computer.

- Mechanisation: Tasks are done by machines operated by people.

- CAD (computer aided design): Used for designing 3-D objects.

- CAM (computer aided manufacture): Computers control machines in the production process.

- CIM (computer integrated manufacture): CAD and CAM are used together. The computer that uses CAD is directly linked with the one that controls the production process.

Here are some things that technology does in shops:

- EPOS (electronic point of sale): When products' bar codes are scanned and the information is printed out on a receipt. Data is also sent to a computer to keep track of stocks.

- EFTPOS (electronic fund transfer at point of sale): When the cash register is connected to the retailer's main computer and banks. The customer's credit/debit card is swiped and the money is debited from the customer's bank account. A receipt is printed out to confirm the transaction.

The advantages of new technology

- Increased productivity.

- Boring jobs done by machines. Boosts motivation.

- Training is needed to operate new machines. Workers become more skilled.

- Better quality.

- Better stock control.

- Quicker communication and reduced paperwork.

- Info is available faster, resulting in faster decision making (for managers).

The disadvantages of new technology

- Unemployment

- Expensive

- To invest in new technology.

- To replace outdated technology.

- To invest in new technology.

- Employees are unhappy with changes in the workplace.

Quality control

There are three ways to control quality:

Quality control

- Involves checking and removing faulty products at the end of the production process.

- Wastes a lot of money.

Quality assurance

- Involves inspecting during and at the end of production.

- Aim to

- Stop faults from happening.

- Set a quality standard that all products have to achieve.

- Stop faults from happening.

- Need teamworking and responsibility.

Total quality management

- Encourages everyone to concentrate on quality.

- Quality is the main aim for all staff.

- Products need to satisfy all customer needs.

среда, 5 апреля 2017 г.

LESSON 9 - BUSINESS BASICS PART II - OPERATIONS MANAGEMENT, CUSTOMER SERVICE, IS & HR

Introduction: The engines of the organization

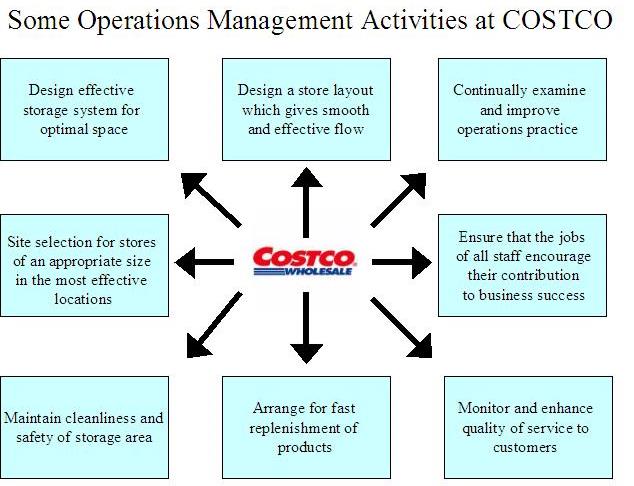

Operations Management has a wide scope of responsibility. It is the area of business that is concerned with the production of goods and services, and involves the responsibility of ensuring that business operations are efficient and effective. To name a few, it is the management of resources, the production and distribution of goods and services to customers, and the analysis of queue systems. It can be the engine to the back office of a bank, retail department store, a manufacturing plant, and even the process of making the food in a restaurant. For example, look at all of the operations management responsibilities of the store COSTCO:

Every day, you use a multitude of physical objects and a variety of services. Most of the physical objects have been manufactured, and people within organizations have provided most of the services. Every organization has an operations function, whether or not it is called “operations,” such as the management of customer service functions like customer care and technical support.

In this lesson will give an overview of the basic functions within operations management. We will also go over Information Systems or IS, and Information Technology or IT. These two functions sometimes are combined into one group so we will discuss them as one unified group. There will be a discussion on disaster planning as well.

We will also discuss customer service and the duties of technical support, along with an overview of Human Resources or HR.

The day-to-day running of a company

Ultimately, the nature of how operations management is carried out in an organization depends greatly on the nature of products or services, for example, retail, service, manufacturing, wholesale, etc. Whatever the system or organization, the functions of operations management are always the same: (1) designing, (2) planning, (3) organizing, (4) directing, and (5) controlling. Management establishes the goals and objectives of the organization and plans how to attain them. Basically operations is about:

- Designing services, products and delivery systems.

- Managing and controlling the operations system.

- Continuously finding ways to improve its operations.

Every organization, be it a product or service organization, transforms certain inputs into outputs. The quality of these inputs is to be monitored regularly to get the desired output. The general model of operations management, which is a transformation process, would look like this transformation model:

A transformation process is any activity or group of activities that takes one or more inputs, transforms and adds value to them, and provides outputs for customers or clients. Transformation processes include:

- Changes in the physical characteristics of materials or customers.

- Changes in the location of materials, information or customers.

- Changes in the ownership of materials or information.

- Storage or accommodation of materials, information or customers.

- Changes in the purpose or form of information.

- Changes in the physiological or psychological state of customers.

In many cases, all three types of transforming input resources, which are materials, information and customers, are transformed by the same organization. For example, withdrawing money from a bank account involves the account information, materials such as dollar bills and checks, and the customer.

A useful way of categorizing different types of transformation within operations management is into:

- Manufacturing – This is the producing of goods and physical creation of products, such as cars, and the running of the factory, which would include purchasing materials and supplies. There would also be inventory responsibilities.

- Transport – This is the movement of materials or customers, such as a taxi service or trucking fleet.

- Supply – This would be the change in ownership of goods, such as a retail store, supermarket, etc.

- Service – This could be considered the treatment of customers or the storage of materials, such as the back office duties of providing customer service in a call center, or warehouses to store goods. Part of service would also be a possible output of customer feedback and return of goods.

Ensuring products are made; inventoried, shipped, received, repaired, and all the while managing the company’s facilities, are considered part of operations management. In some cases, providing customer service functions like support or care, are considered part of operations, although sometimes customer service might be associated with sales, or even an entity unto itself.

Operations Management makes sure the business is running efficiently including employee productivity, delivery, cost control, and quality. The analyzing of processes using both mathematical and scientific data is crucial for optimal performance. With process analysis, you can identify improvements, that will turn into cost savings, which can then be passed on to the customer, streamline the company’s infrastructure, and streamline inventory and supply chain issues. Some typical operating decisions would be:

- How much should you invest in developing new products?

- How much staff and space is needed?

- How do you determine the best buys on expensive items and equipment?

- What are the hours of operation?

- How long should a project take to complete?

- How much inventory is needed?

- How will the products be shipped?

- How will customer satisfaction be measured?

- How will the operating systems, workstations, and physical plant be designed?

- What are the processes and procedures used to ensure smooth operations?

- How to ensure quality and needed quantity of goods or services?

The examples just covered are only a few of the types of decisions an operations manager needs to make. Fortunately, there are many tools like flow charts, project task sheets, and cost/expense tools to help with making these types of decisions in all areas involved within operations management.

Operations managers are usually stereotyped as a plant manager in charge of a factory, however, there are also quality managers, production and inventory control managers, and line supervisors. In service industries, managers in hotels, restaurants, hospitals, banks and stores are operations managers as well. In the not-for-profit sector, the manager of a charity store, nursing home, and day center for older people, are all also considered operations managers.

Basic Decision Making Tools

Cost-benefit analysis is used to see if an investment is worth pursuing. You are measuring the benefits expected from a decision, measuring the costs associated with this decision, and then see if the benefits outweigh the costs. Most businesses have both fixed costs and variable costs. Fixed costsremain the same no matter how much the company makes or sells. Some examples would be the rent on a building, the insurance, exempt salaries, or the lease of a copy machine. Variable costs change with the company’s production and sales volume of a unit. Some examples would be the cost of materials, delivery costs, compensation of the sales team, salaries of non-exempt workers, or the cost of paper and ink of a copy machine. If the benefits outweigh the costs based on analytical data, then you could go ahead with the planned course of action. A good tool to use would be:

o Break-even analysis. It lets you find when you first start making profit. If we were to base this on a product being sold, the formula would be: units sold = the fixed costs ÷ (the selling price minus the variable cost per unit).

A simple example would be if a copy machine is leased for $8,000 per year (which is the fixed cost) and you sell the copy for 10¢ (Selling price) but it costs 3¢ for the paper and ink per copy (the variable cost), the result would be:

$8,000 ÷ ($0.10 - $0.03) or $8,000 ÷ $0.07 which would equal 114,285 copies needed to be sold to break-even. That would be the point in which the machine paid for itself, the break-even point, and from that point on is when you would see profit.

If you are looking at two comparable pieces of equipment, you can use:

o Crossover Analysis. This lets you identify the point where you should switch from one product or service to another one that has similar benefits, but different fixed and variable costs. Using the same copy machine example, which we will call machine 1, and machine 2 that costs $4,000 with variable costs of 5¢ a copy, the formula would be: Crossover units = (machine 2’s fixed cost – machine 1’s fixed cost) ÷ (machine 1’s variable cost – machine 2’s fixed cost). The result would be:

Crossover units = (4,000 - 8,000) ÷ (.03 - .05) or (-4,000) ÷ (-0.02) which would equal 200,000. This means that at 200,000 copies, the total cost of each of the two machines is equal. If you expect to sell more than 200,000 copies then machine 1 would be the best choice. If you expect to sell less than 200,000 copies then machine 2 would be the best choice.

Another example of cost-benefit analysis:

The customer operations manager is deciding whether to implement a new online training program that would cover approximately 33% of the current live based training. There is no budget to hire someone for this job specifically, so a decision needs to be made whether it is worth using an existing staff member to work on this project. A new more robust computer and training software will need to be purchased. Sales and Support will need to be trained as well as the existing customer base. Some production work will be lost due to pulling one person off of their normal duties to work on this project. Some of the work will also be outsourced.

Here is the cost-benefit analysis used to determine if the project is worth pursuing:

Costs:

Online training setup:

· Software for interactive training is $1,000

· 1 new PC dedicated to project is $2,000

· Web page and hosting setup (outsourced) is $10,000

Internal Training costs:

· Training introduction to sales and support of 10 people is $500 each for a total of $5,000

· Training introduction to the customer base of 4 people is $500 each for a total of $2,000

Other costs:

· Lost time: 1 Person for 6 months is $30,000

· Lost production through disruption: estimated $50,000

· Lost time for weekly meetings with key staff throughout project: estimated $10,000

Total cost: $110,000

Benefits:

· Reducing one day of live based training (hotel, training room, etc): estimated $25,000 per year

· Improved training efficiency, resulting in fewer support calls, thus eliminating need to hire additional support staff: estimated $80,000 per year

· Improved retention based on further understanding of product: estimated $40,000 per year

Total Benefit: $145,000 per year

The Break-even point would be $110,000 ÷ $145,000 = 0.76 of a year or approximately 9 months.

The Break-even point would be $110,000 ÷ $145,000 = 0.76 of a year or approximately 9 months.

With this analysis, a decision based on facts, not just speculation, can be made. If needed, this cost-benefit analysis can be given to upper management to evaluate.

Critical Path Method (CPM) will help you plan and coordinate the tasks and activities in a project. CPM analysis requires that you first determine all of the steps necessary to complete the project. You then prioritize based on the steps that are dependant on others steps being completed first, as well as those that can run parallel to other tasks. It is one of the basic tools to use in Project Management. Project Management is the planning, organizing and managing of allocated resources to bring about the successful completion of a specific project.

Lets say you are planning on opening a telephone installation business and already know the main tasks needed to get started. You would assign a code based on each task and put them in order. The order would consist of the task that needs to be done before you can do the next one (predecessor), and how long you think each task will take.

Example – Project Task Sheet

Once you have created the task sheet, you would make a chart that visibly shows each task in relationship to each other, and in order. In this case you would separate what would be facilities related, which is getting the office space ready, and what would be product related, which is getting the phones, staff and training.

Example – Basic CPM chart

The longest path through the project is called the critical path. In the example given, that would be from point A to point I. You can see by this chart that you can do certain tasks concurrently. Since you can do certain tasks concurrently, the total elapsed time would be 21 weeks; even though the total project time is 39 weeks.

PERT (Program Evaluation and Review Technique) is like CRM but the major difference is PERT enables you to make an optimistic, pessimistic and best guess estimate of the time it will take to complete each task of the project. A PERT chart is a project diagram consisting of numbered circles or rectangles representing events, or milestones in the project linked by directional lines representing tasks in the project. The direction of the arrows on the lines indicates the sequence of tasks.

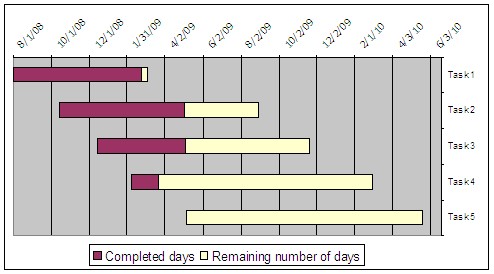

Gantt Chart is used in project management to plan and track the progress of a project. Time is indicated as columns across the chart, with individual tasks represented as bars. The length and position of the bars shows the start date, completed days, and remaining number of days associated with the tasks.

Example – Basic Gantt chart

Decision tree is another visual flow chart tool. It is like PERT, however, it lets you consider choices and risk. It can help when deciding between different options by projecting possible outcomes. It gives the decision maker an overview of the multiple stages that will follow each possible decision. Each branch shows the probability of the outcome. The project, question or event is represented with a square. The decision is represented with a circle. Branches are represented by the choices that you have to make. The probability of each option is shown above each branch. The two or more branches that sprout from the same node must all add up to 100%. For example, if one decision circle has two options with one branch with a probability of 30 percent, then the other branch probability must be 70 percent. The probability percent is based on facts that you have determined, or have been given. You need to have sufficient data to best utilize the probability part of this tool.

Example – Decision tree. A simple analogy based on the decision on whether to invest in an online training program:

There are software tools that are excellent for planning and scheduling projects such as Microsoft Project. There are also excellent software tools to create flow charts like Microsoft Visio. If you are going to be heavily involved with project management duties and/or process documentation, these two tools are a must. It is also suggested that you take a separate project management course.

Quality Management

Quality Management is a method for ensuring that all the activities necessary to design, develop and implement a product or service are effective and efficient. All to often, quality is viewed as simplistic with the simple attitude of putting some quality standards in place and assign people to make sure they’re observed. This is the wrong attitude, as quality, in any aspect of business, should be considered critically important. The attitude within the entire company should be that of accepting nothing but superior quality. Customer loyalty and superior quality go hand-in-hand. Loyalty is a direct result of customer satisfaction. Value is created for the customer, which also results in employee satisfaction. Customers will be less price sensitive and are more likely to recommend your company’s products or services. Most of all, with customer loyalty due to superior quality comes higher profit and growth for the company.

Quality management can be considered to have three main components:

- Quality control - also known as QC and IQC (incoming quality control) which is designed to meet or exceed customer requirements. An example would be a goal of no more than a 2% failure rate, based on random inspection, on the cosmetic look of a phone. The goal is to find ways to lower that percentage without increasing costs.

- Quality assurance - also known as QA, which refers to planned and systematic production and testing processes to ensure proper performance of the product, to minimize defects, and ensure a high degree of quality. An example of a QA goal based on a software release would be a less than 2% trouble ticket rate based on a bug associated with the release.

- Quality improvement - there are many methods and organizations for quality improvement. The bottom line is that they all strive for continuous quality improvement. Three basic rules for managing quality are:

- Upper management must be completely involved and committed to excellence, not just supporting it. They should be willing to allow for independent assessment, accept the findings, and act on them.

- The quality focus must be incorporated throughout the entire company, not just a group or two.

- Quality improvement must be measured both on quality specific terms and the impact it has towards business goals.

Here are six of the most common quality methods and organizations used towards quality improvement:

- Six Sigma - identifies and removes the causes of defects and errors in manufacturing and business processes. It uses a set of quality management methods, including statistical methods, and creates a special infrastructure of people within the organization who are experts in these methods. These experts are considered Green Belts & Black Belts. Six Sigma has two key methods:

DMAIC - which is used to improve an existing business process:

· Define process improvement goals that are consistent with customer demands and the enterprise strategy.

· Measure key aspects of the current process and collect relevant data.

· Analyze the data to verify cause-and-effect relationships. Determine what the relationships are, and attempt to ensure that all factors have been considered.

· Improve or optimize the process based upon data analysis using techniques like “Design of experiments.”

· Control to ensure that any deviations from the target are corrected before they result in defects. Set up pilot runs to establish process capability, move on to production, set up control mechanisms, and continuously monitor the process.

DMADV is used to create new product or process designs:

· Define design goals that are consistent with customer demands and the enterprise strategy.

· Measure and identify CTQ’s (characteristics that are “Critical To Quality”), product capabilities, production process capability, and risks.

· Analyze to develop and design alternatives, create a high-level design, and evaluate design capability to select the best design.

· Design details, optimize the design, and plan for design verification. This phase may require simulations.

· Verify the design, set up pilot runs, implement the production process, and hand it over to the process owners.

- ISO 9000 - is a family of standards for quality management systems. ISO 9000 is maintained by ISO, the International Organization for Standardization and is administered by accreditation and certification bodies. There are eight ISO 9000 2000 quality management principles:

1. Focus on your customers

2. Provide Leadership

3. Involve your people

4. Use a process approach

5. Take a systems approach

6. Encourage continual improvement

7. Get the facts before making decisions

8. Work with your suppliers

- TQM – Total Quality Management is a management approach to long-term success through customer satisfaction. All members of an organization participate in improving processes, products, services and the culture in which they work.

- Kaizen – looks at eliminating waste from the business and production process, thus improving production and reducing costs without much of a monetary investment.

- Benchmarking - is the process of measuring an organization's internal processes, then identifying, understanding, and adapting outstanding practices from other organizations considered to be best-in-class.

- Quality, Cost, Delivery (QCD) – offers a straightforward method of measuring processes while being applicable to both simple and complicated business processes. It also represents a basis for comparing businesses. QCD, as used in lean manufacturing, measures a businesses activity and develops key performance indicators. QCD analysis often forms a part of continuous improvement programs.

Supply Chain Management (SCM)

Supply Chain Management involves the flow of materials, information, and finances as they move in a level process from supplier, to manufacturer, to wholesaler, to retailer, and finally to the consumer. SCM involves coordinating and integrating these flows among all companies involved. Each level of the supply chain is described as a “tier.” There can be several tiers beneath the final supplier.

Example - Supply Chain Management flow chart

In the example given, materials flow downstream through a manufacturing level (tier) transforming the raw materials, which are the components or parts. These are assembled on the next level to form products. The products are shipped to distribution centers, and from there on to retailers and customers.

Logistics Management is the part of SCM that efficiently plans, implements, and controls the delivery and storage of goods and services.

Supply chain management flows can be divided into three main flows:

- Product flow - which is the movement of goods from a supplier to a customer, as well as any customer returns or service needs.

- Information flow - which involves transmitting orders and updating the status of delivery.

- Finances flow - which consists of credit terms, payment schedules, and consignment and title ownership arrangements.

There are three levels of decisions associated with SCM:

- Strategic - Long-term decisions related to location, production, inventory, and transportation.

- Tactical - Medium-term decisions such as weekly demand forecasts, distribution and transportation planning, production planning, and materials requirement planning.

- Operational - Day-to-Day decisions as part of normal managerial duties.

The following five steps are typical purchase procedures:

- Specify the amount needed.

- Determine the supplier based on pricing comparisons.

- Negotiate the price as well as payment terms, warranty, and timed cost reductions. Dealing with supplies or commodities depends on their availability, price and quality.

- Purchase the supplies.

- Delivery and inspection of the supplies.

Focusing on certain areas within the supply chain can reduce costs. There might be times when buying in bulk is cost effective. JIT, FIFO and LIFO will be discussed in the following Inventory Management section of this lesson.

Manufacturing Resource Planning (MRP) as part of SCM can help plan and determine the supply needs and timelines for new manufacturing processes in order to predict product delivery schedules, and respond to changes in the market or product. It is a software based production planning and inventory control system used to manage manufacturing processes. The three major objectives of MRP are:

- Ensure materials and products are available for production and delivery to customers.

- Maintain the lowest possible level of inventory.

- Plan manufacturing activities, delivery schedules, and purchasing activities.

Sophisticated software systems with Web interfaces are competing with Web-based Application Service Providers (ASP) who provide SCM service for companies who rent their service. A number of major Web sites offer e-procurement marketplaces, which is the business-to-business purchase and sale of supplies and services over the Internet. Manufacturers can trade and even make auction bids with suppliers.

The five basic Supply Chain Management steps are:

- Plan – Strategic planning by developing a set of metrics to monitor the supply chain so that it is efficient, costs less, and delivers high quality and value to customers.

- Source – Choose the suppliers that will deliver the goods and services you need to create your product including pricing, delivery and payment. Also managing the inventory of goods and services you receive from suppliers, including receiving shipments, verifying them, transferring them to your manufacturing facilities, and authorizing supplier payments. This is all done while at the same time continuously monitoring the metrics for possible improvement.

- Make – Manufacture your product. Schedule the activities necessary for production, testing, packaging and preparation for delivery. Always measure quality levels, production output, and worker productivity.

- Deliver – Also known as logistics. Coordinate the receipt of orders from customers, develop a network of warehouses, pick carriers to get products to customers, and set up an invoicing system to receive payments. Shipping options can include:

· FOB (Free On Board) Factory Pricing where the buyer bears the shipping cost.

· Freight Absorption Pricing in which paying some of the transportation costs are in line with competitors.

· Uniformed Delivery Pricing in which a standard price is set no matter the location.

· Zone Pricing in which you charge different prices for different geographical locations.

- Return – Also known as RMA or Return Merchandise Authorization. A system for receiving defective and excess products back from customers, and supporting customers who have problems with delivered products.

Inventory Management

Inventory Management keeps track of goods and materials held available in stock. It allows the management of sales, purchases and payments. Inventory management software, such as Fishbowl, helps create invoices, purchase orders, receiving lists, payment receipts, and can print bar-code labels. An inventory management software system configured to a warehouse, retail, or product line, will help create revenue for the company and control operating costs. Here are five common inventory phrases:

- SKU – Stock-Keeping Unit (pronounced Skew) is a unique combination of all the components that are assembled into the purchasable item. Therefore, any change in the packaging or product is a new SKU. This level of detailed specification assists in managing inventory.

- BOM - Bill of Materials (pronounced bomb) is the term used to describe the raw materials, parts, sub-components, and components needed to manufacture a finished product. A BOM can define:

· Products as they are designed, which is an engineering BOM.

· As they are ordered, which is a sales BOM.

· As they are built, which is a manufacturing BOM.

· As they are maintained, which is a service BOM.

- JIT – Just-in-Time – JIT is the practice of keeping very low levels of inventory and using sophisticated ordering and manufacturing methods to get the product into inventory just in time to be shipped. The goal is to maximize inventory turnover, and minimize the money tied up in inventory.

- FIFO – First in First out (pronounced Fife-oh) - FIFO is pushing the old items up front to make room for new items in the back that are of the same kind. Items that are perishable and have a sell by date such as milk and eggs, or if you have a product that has periodic software upgrades, would use the FIFO method. You would want to use FIFO to reduce old stock in order to make way for the new stock.

- LIFO – Last in First out (Pronounced Life-oh) – LIFO is pushing the old items back to make room for new items in the front that are of the same kind. The last items stocked will be the first items sold. This would be a typical stocking method for items that have no “sell-by” date associated with them, or at least one that is in the distant future, such as canned goods or a product that has no upgrade scheduled for awhile, etc.

COGS, LIFO and FIFO as pertained to accounting is discussed in Lesson 8.

Disaster Planning and Recovery

Although this might not be considered an operations responsibility, it still needs to be discussed. Disaster planning and recovery needs to be fully investigated on just how the company would react to disasters such as hurricanes, fires, major power outages, and even terrorism. Disaster planning and recovery should not only be planned for emergencies that would require evacuation or first aid, but also for recovering important company information.

First off the goal should be prevention. This especially holds true for potential internal disasters, as you have more control to prevent disasters from happening.

If disaster strikes, however, you need to be prepared. At least a couple of company personnel should have CPR training. There should be clear and precise directions posted everywhere regarding evacuation procedures. Management protocols need to be determined on how to make sure everyone has been accounted for, and for any additional steps that need to be taken. There also needs to be first aid kits and fire extinguishers located throughout the premise.

One example of planning ahead to recover from an internal company disaster would be by regularly backing up all data externally through an online backup service. You might even work in an organization, such as a telephone service provider, who should have a backup plan in order to continue to provide service to its customers during a major disaster.

Here is a list of organizations that can help with disaster preparation strategies:

FEMA (Federal Emergency Management Agency)

Make it a point to make sure your company has preventive measures in place, and is able to react to the best of its abilities to any possible emergencies or disasters.

Customer Service – Customer Care and Technical Support

Customer Service covers a vast array of support functions. It can be associated with technically supporting the customer, taking orders, collecting payments, booking flights, etc. Customer Service provides support to customers before, during, and after the purchase of a product or service. The rapid resolution of customer complaints about quality, defects, and delivery is essential. Customer service can either save or lose the account based on how the situation is handled. They also know the everyday problems customers face and learn more about product strengths and weaknesses than anyone else in the company. They will then be able to provide input to the design engineers, who can then make future products easier to use. In fact, customer service trends should be the first item discussed during management meetings.

On the other hand, word of mouth about bad customer service spreads just as it does about a good product. A potential future customer might not buy the product or service based on just a few negative comments, blogs, etc. Poor sales and possible churn (losing customers) can have nothing to do with the quality of the product or the sales-force selling the product, but poor customer service. Good customer service, however, can lead to better sales and retaining customer loyalty, thus increasing company longevity. Customer service is more than just supporting a customer, it can be a tool to improve sales or be the culprit of financial loss.

Even though customer service might fall under sales or marketing’s responsibility, it can also be considered part of the back office operations group. For that reason we will discuss customer service in this lesson. You can also relate customer service to marketing and sales, which will be discussed in lesson 10.

First, lets determine what is a customer and who are they? In its most basic terms, a customer is an individual or organization that will benefit from the products and/or services the company offers. Customers may fall into one of three customer groups:

- Existing Customers who have purchased or used the company’s products and/or services within a designated period of time. For some organizations the timeframe may be short, for instance, a restaurant may only consider someone to be an existing customer if they have purchased within the last couple of months. Other companies may view a customer as an existing customer even though if they have not purchased anything in the last few years, for example, a computer manufacturer. Existing customers are extremely important since they have a current relationship with the company, and they give the company a reason to remain in contact with them. They represent the best market for future sales, especially if they are satisfied with the relationship they presently have with the company. Getting these existing customers to purchase more is significantly less expensive and time consuming than finding new customers, mainly because they are satisfied with the company. They should be easy to reach with promotional appeals such as discounts for a new product.

- Former Customers who previously purchased from your company, however, they are not considered and Existing Customer anymore because they have not purchased within a certain timeframe. In most cases it is due to competition or because they did not receive good customer service.

- Potential Customers who have yet to purchase, but have the requirements to eventually become Existing Customers. They have a need for a product, possess the financial means to buy it, and have the authority to make a buying decision. Targeting markets to find these potential customers will be discussed in lesson 10.

By understanding the different customer types, it is clear to see that it is not only marketing or sales that should be concerned, it should also be customer service. An Existing Customer might turn into a Former Customer if they receive poor customer service. A former customer will most likely never come back due to poor customer service. A Potential Customer might be put off if they read any negative blogs or hear bad comments. Bad word of mouth can potentially kill new customers.

Quite often the customer will complain directly to the sales person, who will then try to resolve the issue the best they can. This should not be the case. The customer should have high confidence in the customer service department and not even have to bother the sales person. Besides, sales should be selling, not supporting. One issue regarding sales, however, is when a sales person promises something that can’t be delivered, or that they do not fully understand just what it is they are selling.

It is so important that the constant drive to satisfy customers is a priority for the customer service manager. Customer service must appreciate the role customers play in helping the company meet its goals. Customers are the reason a company is in business. Without customers, or the potential to attract customers, a company is not viable. The more customer service realizes this fact, the better the customer service will be given.

The most common form of customer service is the support of a service in a call center environment. Queue theory is used to determine how many agents are needed to minimize wait time, thus increasing value and providing a better customer experience. For example, if a customer has to wait on hold for longer than 30 seconds, there is loss in value. Queue theory can be used for any type of service related situations, for example, how many checkout counters are needed at a store, etc. Basically, when people have to wait there is loss in value. However, if there are too many employees in too many checkout stands, there is higher cost associated with the service provided. The goal of queuing theory is to find the perfect balance where the wait time does not lose too much value, and the costs are not too high. There are many software programs, such as Blue Pumpkin, that analyze these types of formulas and algorithms.

The most important aspect of customer service is the high level of customer satisfaction based on the customer’s expectations, as described in the examples used in lesson 2. No matter the type of a customer service organization, the goals of service excellence are the same:

- Customer friendly attitude. This includes creating a positive experience by being happy and willing to help, respectful, communicating with the individual as a person, relating to the situation with empathy and understanding, developing a personal connection, going the extra mile, following it to the end, and having grace under pressure. A communication style that builds a bridge instead of a wall is key.

- Technically proficient. Being a customer friendly representative is important, but if the representative does not know what they are doing, it will create a bad customer experience. Proper training, providing the right materials, and using the right tools, is essential in providing excellent customer service.

- Understands the expectations, values and goals for the self and company. Representatives might be friendly and technically proficient, however, they also need to know what is expected of them, and what their company is all about. Clearly defined goals, clear expectations, knowing just who their customers are (internal and/or external), and understanding the company’s values provides the awareness needed to understand the employee’s role in the company. The more motivated the employee, the higher standard of customer service will be given.

Customer satisfaction surveys should be given to measure the success of the customer service department. Data should be gathered in an objective and consistent fashion. The data should never be manipulated, and to ensure objectivity, be given by a third party outside observer.

An interesting paradox regarding customer service surveys is the hidden traps between a “completely satisfied customer” and a “satisfied customer.” A completely satisfied customer will be very loyal, whereas the satisfied customer is easily swayed to switch to a competitor. Although the overall results of the survey will still look positive, you should still be concerned of the “satisfied” or “average” results.

Customers are used to outstanding, low cost, quality based products and services. They now expect outstanding customer support. This is where many companies fail. Many times customers will not even state the reason why they stopped doing business with a company. However, in many cases, research shows it was due to previous trouble reports, which then pointed to poor customer service. When customers have to deal with customer service, they want, in this order:

- Knowledgeable employees who can identify the customers’ true needs.

- First call resolution (no repeat issues).

- To be treated with respect and that they are truly valued.

- An employee who is truly trying to meet their needs.

- To be taken care of as quickly as possible.

These five attributes, in conjunction with the three service excellence goals as previously stated, are the core basics in providing an excellent customer experience. Structuring the department to its optimum and building a strong motivated team will increase the possibilities in providing service excellence.

Even when excellent customer service is provided, there will still always be an upset customer. Whether it is a customer service representative, or even a member of upper management, the next 5 steps are very useful when dealing with an upset customer:

- First, just listen. Let the upset customer get it out of their system. In time they will start to calm down. If they start being abusive, just calmly state, "I understand you are frustrated, and I want to help you, but let's please remain professional."

- Be sympathetic and empathetic. Make sure the customer knows that you understand their frustration. Recognize how it must have felt to be the customer in this situation. Reiterate the customer's complaint so that they know you are truly listening, understand, and care about the situation. Let the customer know you are sorry they have had such a tough time. Even if it's not the company's fault, many times an irate customer just wants to know someone cares that they are inconvenienced. A simple, "I'm so sorry this happened," will normally do. If you find that your company is at fault, definitely apologize again. Be sure to be sincere.

- Let them know that you want to fix the problem and make them happy. A good rule of thumb is to put yourself into their shoes, and between the two of you come up with a solution. The customer will feel that they were heard. Once everything has been stated, it is a good idea to recap the agreed upon solution. Thank them for taking the time to speak with you. It is all right to say you’re sorry, even if the problem was not related to you or the company.

- Document everything. This will let the next representative who might interact with the customer know what the customer has previously experienced. It could be a touchy credit request or repeat issue in which they will not want to have to explain everything all over again. It can also be used to track for possible trends if the problem happens to other customers. Excellent documentation cannot be stressed enough…